Pharmaceuticals Rubber Stoppers

Product Details:

- Diameter As per requirement: Common are 13mm/20mm/28mm

- Resistance level Excellent chemical and thermal resistance

- Compression Ratio 30~35%

- Thickness Customized/Standard depending on type

- Usage & Applications Pharmaceutical sealing, closure of injection vials, bottles, and other pharmaceutical containers

- Natural Rubber Available (also butyl rubber options)

- Size 13mm, 20mm, 28mm, other standard pharma sizes

- Click to View more

Pharmaceuticals Rubber Stoppers Price And Quantity

- 100000 Piece

- 1.00 - 10.00 INR

- Yes

- Cool, dry, away from direct sunlight

- Available on request

- 5 years in unopened packaging

- Autoclave, Gamma Irradiation, Ethylene Oxide (EtO)

- Conforms to USP/EP standards

- <0.25 EU/ml (for sterile pharmaceutical use)

Pharmaceuticals Rubber Stoppers Product Specifications

- Rubber stopper/closure

- Rubber Stopper

- Rubber Polymer, Fillers, Additives, Pigments

- 1.25 Gram per cubic centimeter(g/cm3)

- 0.5%

- 13mm, 20mm, 28mm, other standard pharma sizes

- 7 MPa

- 45~55 Shore A

- Approx. 0.5~2g (varies by stopper size)

- Available (also butyl rubber options)

- Customized/Standard depending on type

- Pharmaceutical sealing, closure of injection vials, bottles, and other pharmaceutical containers

- Low

- 0.2 mm

- Plain/Serum/Blood Collection/Flip Off compatible

- 1.5%

- 1.5%

- 30~35%

- Grey, Red, Black, Custom upon request

- As per requirement: Common are 13mm/20mm/28mm

- Excellent chemical and thermal resistance

- Yes

- Cool, dry, away from direct sunlight

- Available on request

- 5 years in unopened packaging

- Autoclave, Gamma Irradiation, Ethylene Oxide (EtO)

- Conforms to USP/EP standards

- <0.25 EU/ml (for sterile pharmaceutical use)

Pharmaceuticals Rubber Stoppers Trade Information

- 100000 Piece Per Week

- 15 Days

- All India

Product Description

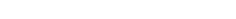

We have established ourselves as a renowned manufacturers, supplier and trader of superior quality Pharmaceuticals Rubber Stoppers. Manufactured using high-grade rubber, obtained from the authorized vendors, these products are offer perfect sealant and prevents contamination. These Pharmaceuticals Rubber Stoppers are manufactured in our huge infrastructure facility, equipped with latest tools and machinery. We offer these Pharmaceuticals Rubber Stoppers in various colours such as Grey, Brown, Black, Blue to meet the requirements of our valued clients.

Product Specification

Material | rubber |

Type | Rubber Stopper |

Diameter | 13 to 33mm |

Color | Grey, Red |

Brand | Shyamwell Pack |

Shape | Round |

Robust Sterilization Compatibility

Our rubber stoppers are engineered to withstand multiple sterilization processes, including autoclave, gamma irradiation, and Ethylene Oxide (EtO). This flexibility accommodates diverse pharmaceutical manufacturing protocols, ensuring reliable and versatile seals under varying conditions. Rigorous material selection and process control guarantee consistent performance during sterilization, maintaining the integrity and safety of pharmaceutical products.

Meets Stringent Quality Standards

Every batch of rubber stoppers is tested to comply with USP/EP extractables and leachables criteria, along with maintaining endotoxin levels below 0.25 EU/ml. The products are phthalate-free and crafted using high-grade raw materials. This focus on quality safeguards patient health and supports regulatory compliance for pharmaceutical packaging applications.

Customizable for Diverse Applications

Available in standard pharma sizes13mm, 20mm, 28mmand multiple styles, including serum and flip-off compatible variants, our stoppers fit most pharmaceutical closures. Custom colors, branding, and dimensions can be provided to match your operational or branding requirements. The versatility in design ensures suitability for sealing injection vials, bottles, and specialty containers.

FAQs of Pharmaceuticals Rubber Stoppers:

Q: How are these pharmaceutical rubber stoppers sterilized for safe use?

A: The stoppers are compatible with autoclave (steam), gamma irradiation, and Ethylene Oxide (EtO) sterilization methods. Select the appropriate process based on your pharmaceutical application and validated procedures, ensuring the stoppers integrity and safe use.Q: What ensures the safety and quality of these rubber stoppers in pharmaceutical applications?

A: The stoppers are manufactured to conform with USP/EP extractables and leachables standards, exhibit endotoxin levels below 0.25 EU/ml, and are free from phthalates. They are subjected to strict quality controls, making them safe and compliant for critical pharmaceutical sealing needs.Q: When should I replace unopened rubber stoppers in inventory?

A: It is recommended to use the rubber stoppers within five years of manufacturing, provided they remain unopened and are stored under cool, dry conditions away from direct sunlight. Expired or compromised packaging could affect their performance and sterility.Q: Where can these stoppers be used within pharmaceutical processes?

A: These rubber stoppers are designed for sealing and closing injection vials, bottles, and various pharmaceutical containers needing robust protection from contamination or leakage. Industries such as injectables, biologics, and diagnostics benefit widely from their use.Q: What are the customization options available for these stoppers?

A: Custom branding, colors, and sizes are available upon request. Clients can specify dimensions, styles (plain, serum, blood collection, flip-off compatible), and require custom labeling to meet branding or operational requirements.Q: How do these stoppers benefit pharmaceutical manufacturers?

A: Manufacturers gain from the stoppers excellent chemical and thermal resistance, secure sealing capability, regulatory compliance, long shelf life, and adaptability to various closure systems. These features help ensure drug safety, product stability, and ease of use.Q: What should be the storage conditions to maintain stopper quality?

A: Store the stoppers in a cool, dry environment away from direct sunlight. Keeping them in unopened packaging within the recommended temperature and humidity parameters preserves their chemical stability and sealing performance throughout their shelf life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+