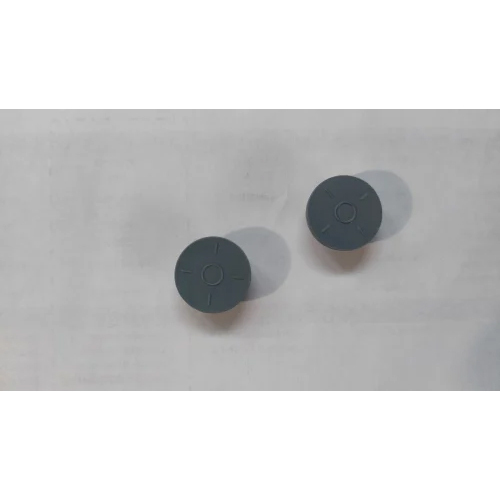

उत्पाद वर्णन

Discover top-tier sealing with our 20MM Bromobutyl Rubber Stoppercrafted for ineffable performance across pharmaceutical and biological applications. Access peace of mind with its marvelous resistance to chemicals and gases, secured by non-reactive, non-porous properties. Select from sterile or non-sterile options, all boasting an ultra-low endotoxin level (<0.5 EU/piece) and compliance with USP, EP, and ISO 8871-1 standards. Gilt-edged features like double PE bag packaging, tight tolerances, gamma, steam, or ETO sterilization compatibility, and prolonged shelf life ensure utmost reliability for injectable medicines and sensitive vial preparations.

Innovative Plant Application and Distinct Competitive Advantages

The 20MM Bromobutyl Rubber Stopper is tailored for seamless use in automated filling and capping lines within pharmaceutical plants, supporting high-throughput operations. Its non-porous, airtight design, superb chemical resistance, and low extractable profile guarantee preservation of formulation purity. Competitive advantages include customizable stylesplain, slitted, or flangedoffering flexible application methods based on specific vial types. Cleanroom packaging safeguards microbiological quality, positioning this stopper as a preferred choice for sensitive procedures.

Swift Delivery, High Supply Ability, and Secure Packaging

Experience prompt delivery and high supply ability for the 20MM Bromobutyl Rubber Stopper, ensuring uninterrupted operations at the lowest price. Orders are efficiently managed from exchange through order completion. Every stopper is doubly protected with PE bags and sturdy carton boxes, maintaining sterility during transit and storage. Our packaging and delivery system minimizes product risk, allowing bulk or custom order fulfillment to meet project timelines while delivering consistent quality you can rely on.

FAQs of 20MM Bromobutyle Rubber Stopper:

Q: How is the 20MM Bromobutyl Rubber Stopper sterilized for pharmaceutical use?

A: This stopper is compatible with gamma, steam, and ETO sterilization, allowing flexibility according to industry sterilization protocols. Sterilization ensures it meets stringent microbiological quality standards.

Q: What advantages does the stoppers gilt-edged composition provide to injectable medicine storage?

A: The stopper features marvelous chemical and gas resistance, a non-porous design, and low extractable levelsensuring airtight seals and maintaining medicine stability for critical pharmaceutical and biological applications.

Q: Where is the 20MM Bromobutyl Rubber Stopper most commonly applied?

A: It is widely used for sealing pharmaceutical vials and bottles, particularly for injectable medicines, vaccines, and other sensitive preparations requiring strict containment and sterility.

Q: What is the delivery process and timeframe for bulk orders of these stoppers?

A: Once an order is confirmed and payment exchanged, our streamlined logistics ensure prompt order completion and swift dispatch. High supply ability ensures we meet routine and urgent demand within expected delivery windows.

Q: How does the packaging of the stopper uphold its sterile condition?

A: Each stopper is securely packed in double PE bags, then placed in a carton box to prevent contamination, preserve sterility, and facilitate safe transport and storage.