Trusted company that deals in quality-made products

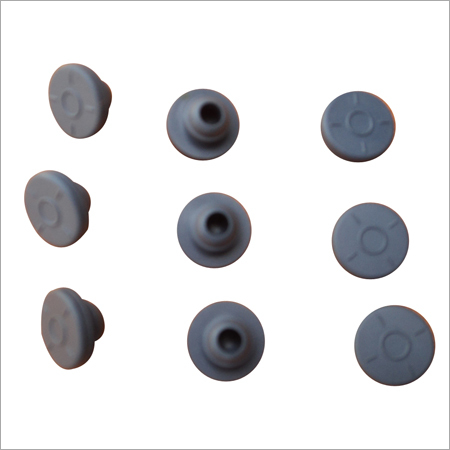

Medicine Bottle Rubber Stopper

1.00 - 10.00 INR

Product Details:

- Ash % Less than 1%

- Product Type Rubber Stopper

- Weight 1g to 6g (depends on size)

- Diameter 13mm, 20mm, 28mm (other sizes on request)

- Water Absorption Negligible

- Thermal Conductivity Very low

- Width Customizable as per bottle design

- Click to View more

X

Medicine Bottle Rubber Stopper Price And Quantity

- 1.00 - 10.00 INR

- 100000 Piece

- Excellent sealing under pressure

- Sterile PE bags, carton or custom on request

- Available

- Autoclavable, suitable for gamma and ethylene oxide sterilization

- Meets European Pharmacopoeia standards

- Conforms to pharmacopeial standards for low extractables

- Up to 3 years under recommended storage

- Odorless

Medicine Bottle Rubber Stopper Product Specifications

- Single piece molded rubber

- Grey, Black

- Very low

- Customizable as per bottle design

- Stopper

- Less than 1%

- Rubber Stopper

- 13mm, 20mm, 28mm (other sizes on request)

- Negligible

- 1.5 Gram per cubic centimeter(g/cm3)

- 1g to 6g (depends on size)

- Less than 2%

- High chemical and temperature resistance

- Good resilience, up to 20%

- As per specific bottle neck

- 13mm, 20mm, 28mm or as required

- 0.2 mm

- Slotted and Plain

- Yes, with synthetic blends

- Sealing medicine bottles, pharmaceutical packaging, lab use

- Matt finish, smooth

- Excellent sealing under pressure

- Sterile PE bags, carton or custom on request

- Available

- Autoclavable, suitable for gamma and ethylene oxide sterilization

- Meets European Pharmacopoeia standards

- Conforms to pharmacopeial standards for low extractables

- Up to 3 years under recommended storage

- Odorless

Medicine Bottle Rubber Stopper Trade Information

- 100000 Piece Per Week

- 15 Days

- All India

Product Description

We are counted among the leading manufacturers, traders and suppliers of Medicine Bottle Rubber Stopper. We manufacture these products in our well-equipped infrastructure facility making use of best-in-class rubber obtained from the reputed vendors of the industry. These products are reliable for sealing bottles and in injecting drugs and chemicals into the bottle. As the Medicine Bottle Rubber Stopper prevents contamination of chemicals and samples, these products are widely demanded in the market.

Product Specification

Material | rubber |

Type | Rubber Stopper |

Diameter | 13 to 33mm |

Color | Grey, Red |

Brand | Shyamwell Pack |

Shape | Round |

Superior Sterilization Compatibility

Our rubber stoppers are engineered to withstand autoclave, gamma, and ethylene oxide sterilization. This flexibility allows for easy integration into different pharmaceutical sterilization workflows, ensuring safety and effectiveness without compromising stopper integrity or performance.

Pharmacopeial Compliance for Safety

These stoppers strictly conform to international pharmacopeial standards for low extractables and heavy metal absence, fostering reliable, contaminant-free sealing of medicine bottles. Rigorous testing ensures optimal air tightness under pressure, essential for preserving pharmaceutical quality.

Customizable Design Options

Available in a variety of sizes (13mm, 20mm, 28mm, or custom), colors (black, grey), and styles (slotted, plain), our stoppers can be personalized with your logo and specific packaging preferences. Options include sterile PE bags, cartons, or tailored solutions to meet branding and operational needs.

FAQs of Medicine Bottle Rubber Stopper:

Q: How are these rubber stoppers sterilized and which processes are compatible?

A: These medicine bottle rubber stoppers can be sterilized by autoclaving, gamma irradiation, and ethylene oxide methods, ensuring suitability for different pharmaceutical and laboratory sterilization requirements.Q: What benefits do low extractables and heavy metal compliance offer?

A: Low extractables prevent contamination of medicines, and heavy metal compliance with European Pharmacopoeia standards guarantees the stoppers are safe for pharmaceutical applications without introducing toxic substances.Q: When should I choose custom logo or packaging options?

A: Custom logo and packaging options are ideal when you want to strengthen your brand identity or require specialized packaging for logistical or aseptic handling needs. These features are available upon request.Q: Where can these rubber stoppers be applied?

A: They are primarily used in sealing medicine bottles, pharmaceutical packaging, and lab containers. Their versatility allows use across pharmaceutical manufacturing, research labs, and healthcare facilities.Q: What is the process for ordering specific sizes or styles?

A: You may select from standard sizes (13mm, 20mm, 28mm), colors, and styles (slotted or plain). For unique bottle designs or requirements, custom sizes and features can be requested during the ordering process.Q: How does excellent air tightness benefit pharmaceutical storage?

A: Superior air tightness maintains bottle integrity under pressure, prevents moisture or air ingress, and helps preserve the quality and efficacy of pharmaceutical contents during storage and transportation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email